Overview of High-power Servo Control System in the Future New Era

↓ Background: China lacks high-end products driven and controlled by high power:

Large-tonnage goods should be handled and sorted with powerful drives, powerful controls, and high reliability. Highly integrated, autonomously controllable, small and precise control units are core components. But high-end industrial control systems in the field of logistics have been monopolized by long-established foreign companies, which feature high costs, long delivery time, and failure in the purchase. Meanwhile, the industrial control system made in China is at a distinct disadvantage in function, control accuracy and stability. The high-performance industrial control system largely depends on imports, with a low domestic production rate of key components.

↓ The original core technology to solve sore points:

Large-tonnage goods should be handled and sorted with powerful drives, powerful controls, and high reliability. In particular, highly integrated, autonomously controllable, small and precise control units are core components. But high-end industrial control systems in the field of logistics have been monopolized by long-established foreign companies, which feature high costs, long delivery time, and failure in the purchase. Meanwhile, the industrial control system made in China is at a distinct disadvantage in function, control accuracy and stability. The high-performance industrial control system largely depends on imports, with the domestic production rate of key components reaching roughly 10%.

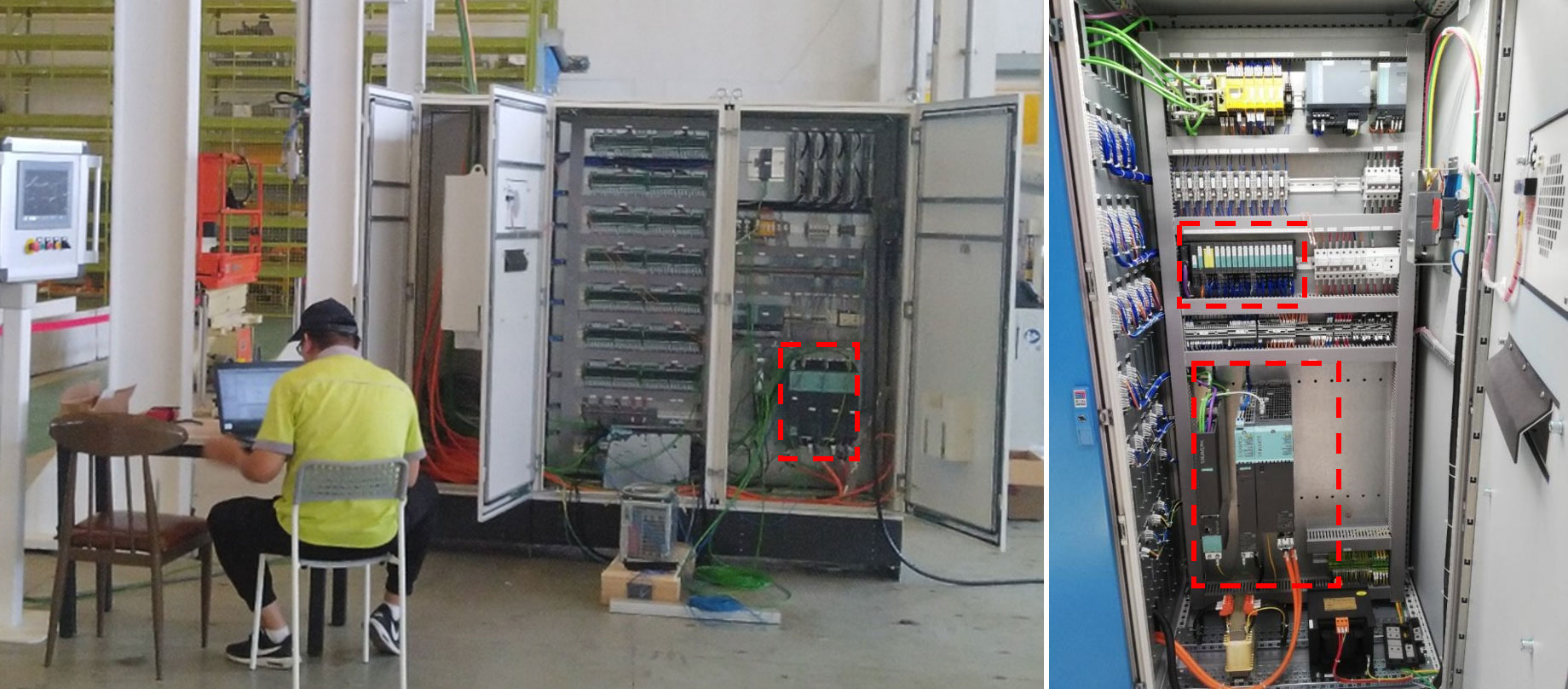

STON Robot has been devoted to developing the core control system since 2016, which creatively developed a rack free control system abroad in 2021. Based on the idea of dimension reduction, the most advanced technology was first encapsulated. Next, the complicated industrial robot control system was turned into a consumer product that is as simple and usable as home appliances. Through this, the traditional electrical control method is transformed into a low-code database software control method. There is the first case worldwide, filling the blank field at home and abroad. The rack free control system is a new robot control technology developed for the large logistics sorting industry, which redefines the technical standards of the large logistics industry and raises them to a new height through completely subverting the logistics sorting method. The high-end high-power rack free control system broke up the foreign monopoly via import substitution based on the idea of dimension reduction. The project product is in conformity with the high-quality development planning of Jiangsu's "14th Five-Year Plan" manufacturing industry, belonging to the high-end equipment cluster - industrial robot industry. Conforming to the needs of the national development strategy, it is essential for the independence and localization of logistics, warehousing and sorting equipment in China.

↓ Value of Rack Free System:

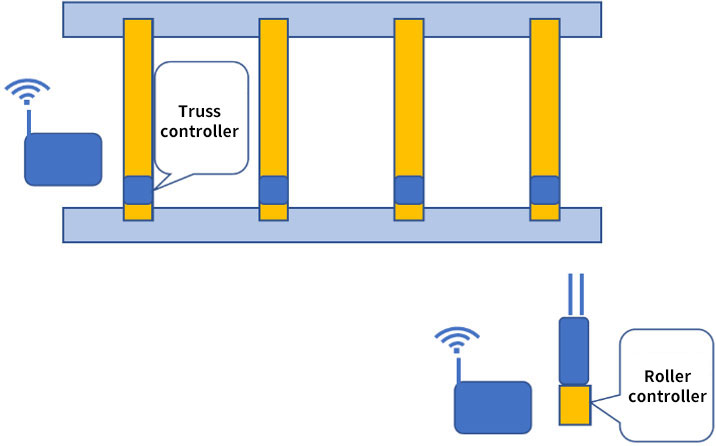

The truss robot becomes less complicated just like a home appliance (free of installation, commissioning, programming, operation, and maintenance);

The cost of the truss robot is low, with the cost performance being superior to the automatic three-dimensional warehouse and forklift yard;

The truss robot forms a technical advantage of dimension reduction in the logistics yard;

Rack Free Control System Dimension reduction application

Sore points It is hard to find a good operation control engineer/ IT engineers can be recruited easily.

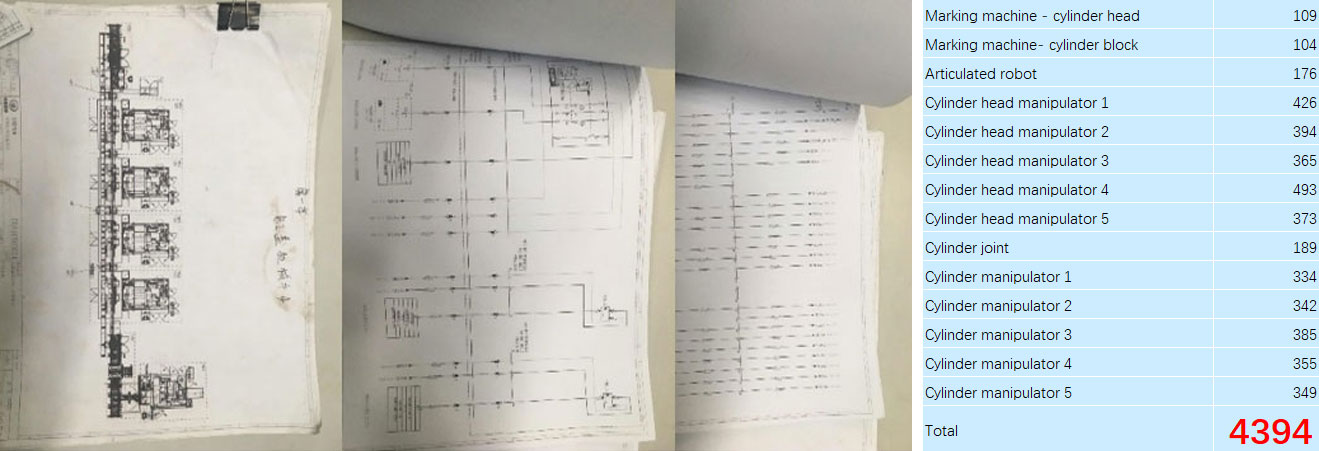

↓ Quantity of electrical drawings of an automobile engine block project

Nearly 9 packs of A4 paper / in 3 months

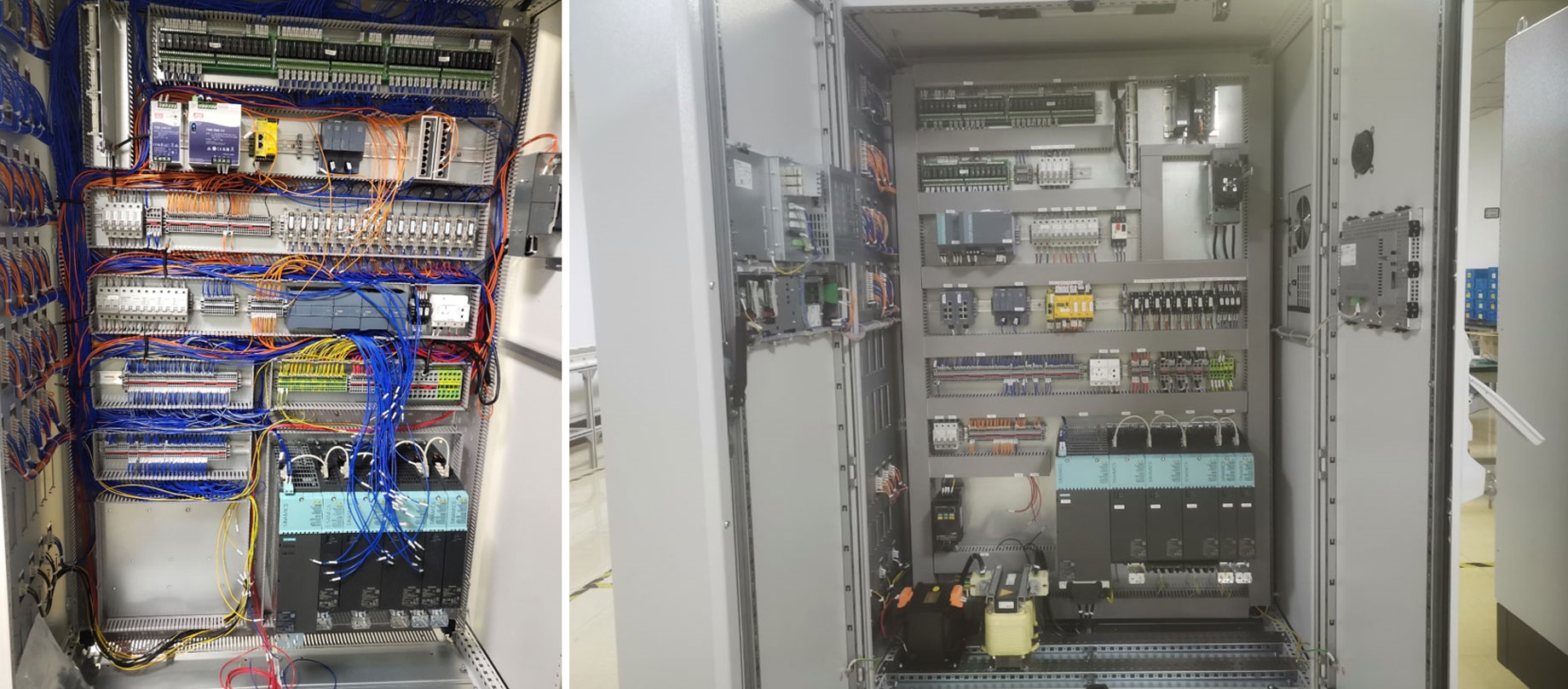

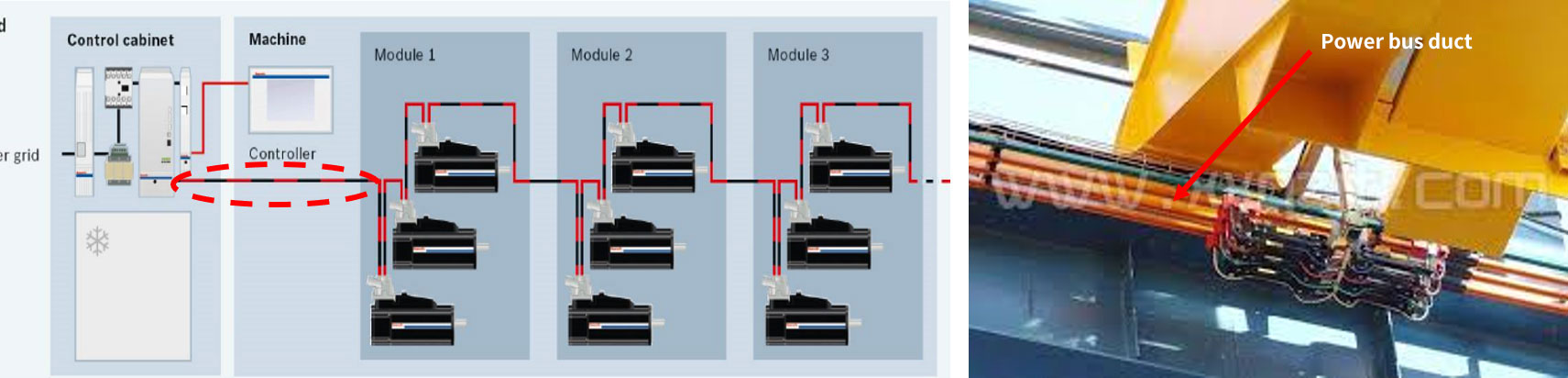

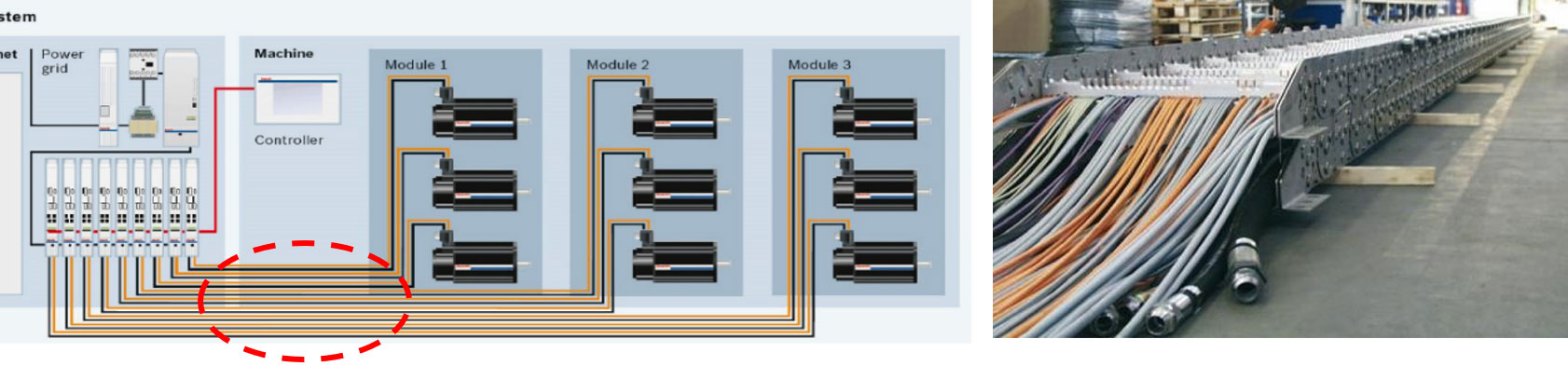

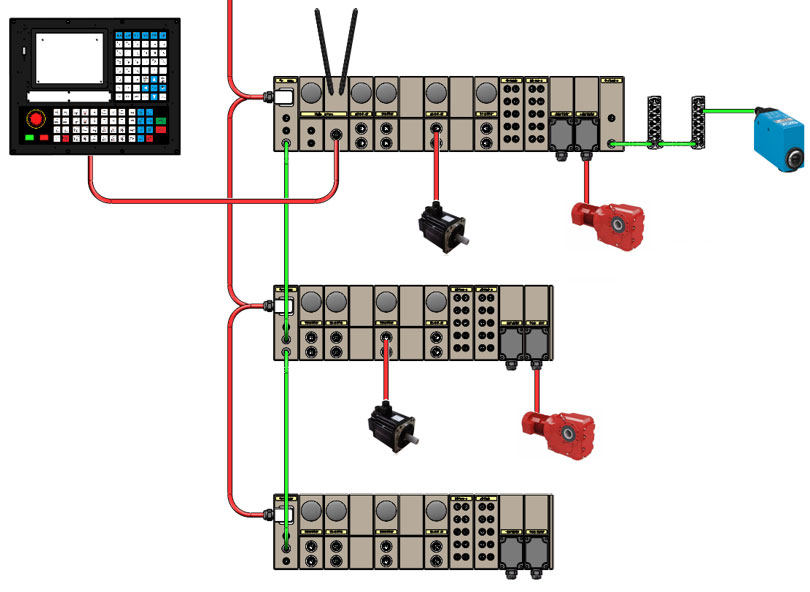

Comparison of distributed control and traditional centralized control

Distributed drive There is only one power bus or busway without any long-travel cables or energy chains.

Centralized control Each motor is independently equipped with power lines, control lines, and communication lines, which generally require dozens or even hundreds of cables that should be replaced every 5 years on average.

-

It is just a traditional centralized wiring method.

(Each line must be connected to the control cabinet)

-

Equal ring network wiring method

(one power line and one bus)

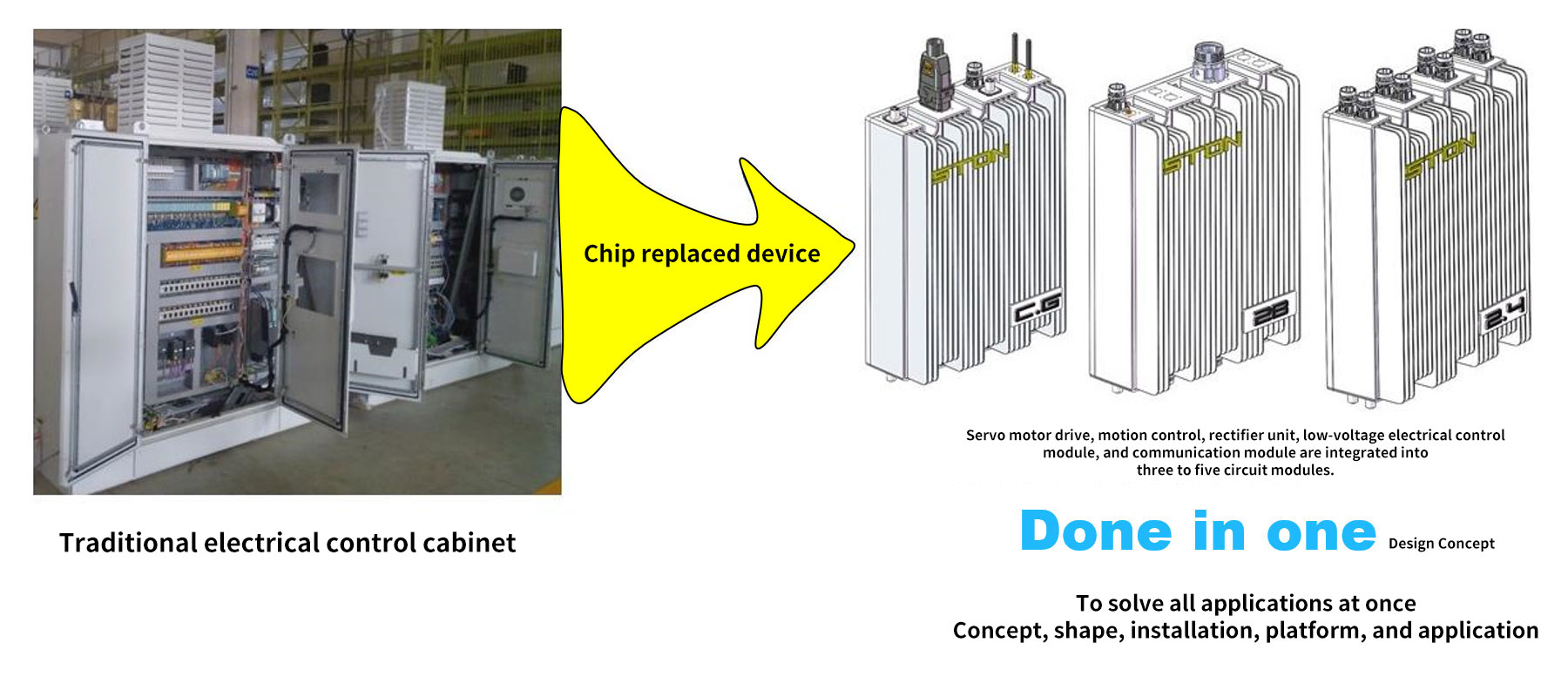

Theoretical and technological innovation The bulky and complex electrical control cabinet is concentrated into modules with all functions of various components achieved by chips.

Theoretical and technological innovation: Originality

-

Rack Free Control System

-

Traditional foreign control system

With the traditional electrical control cabinet completely abolished

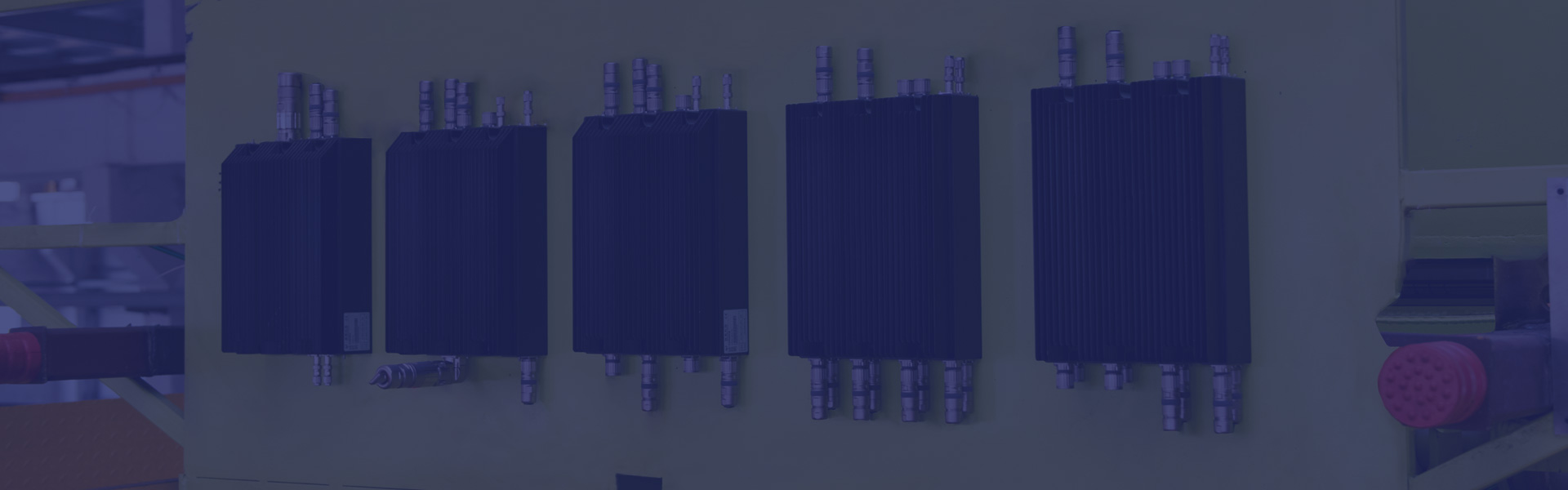

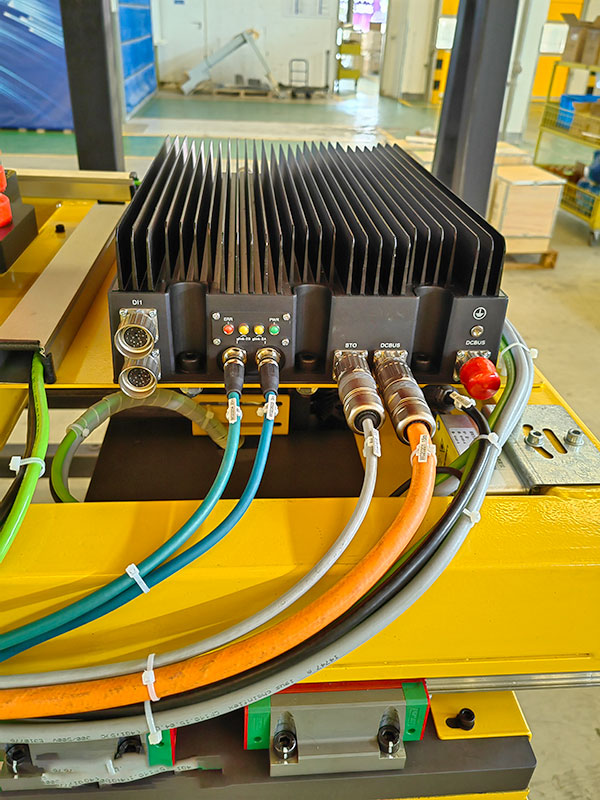

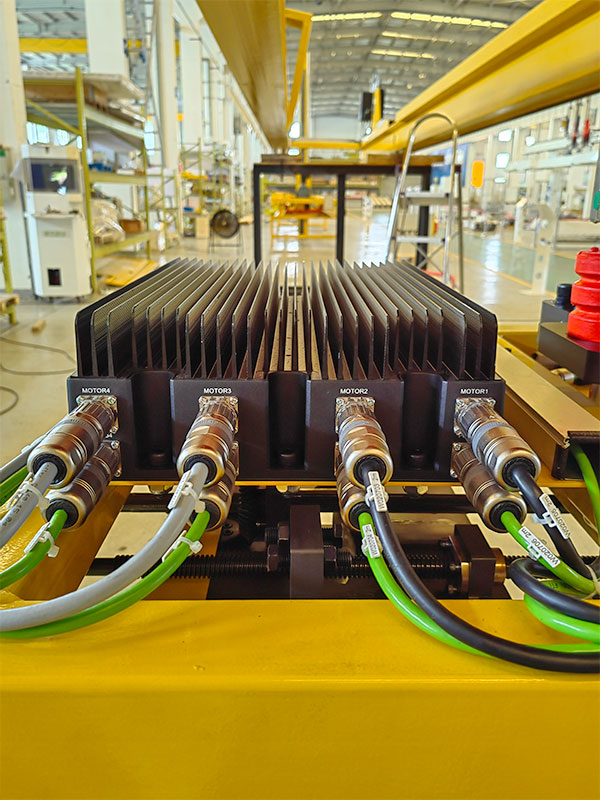

SU30Rack Free Control System It is named after the driver with SUPER+30KW power, where SU (SUPER) means super controller and is made in SU.

-

-

To solve all applications with modules of the same shape.

20kg

IP67

Rectification

Controller

Drive

30kw

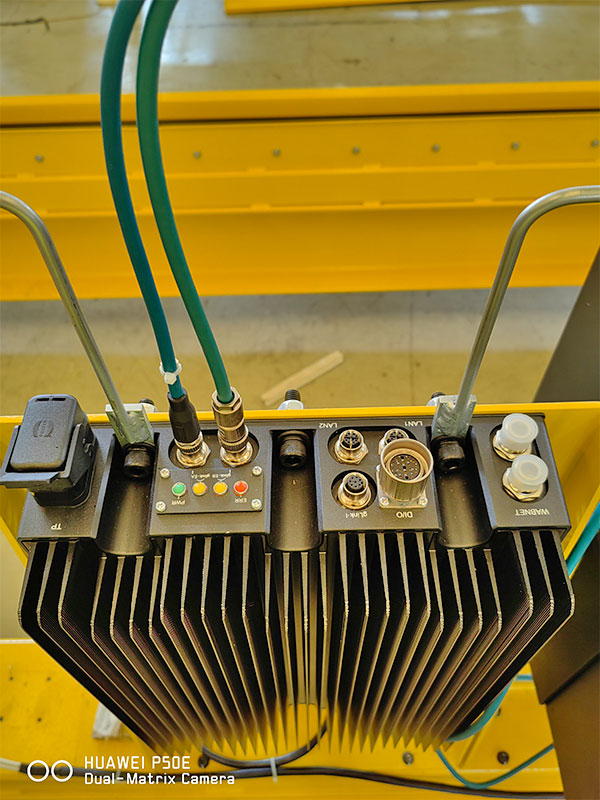

Gigabit ring network

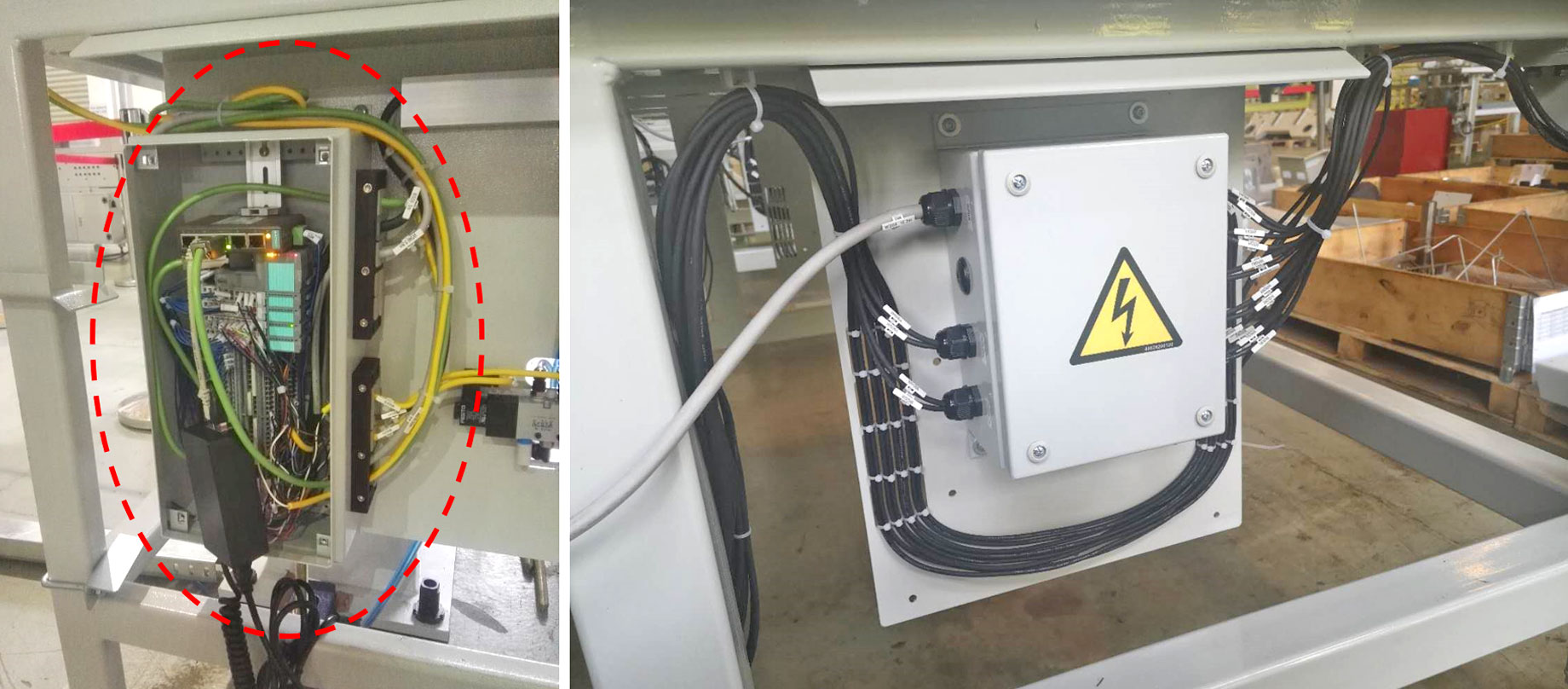

The independent gigabit ring network bus technology is utilized in the rack free system.

-

-

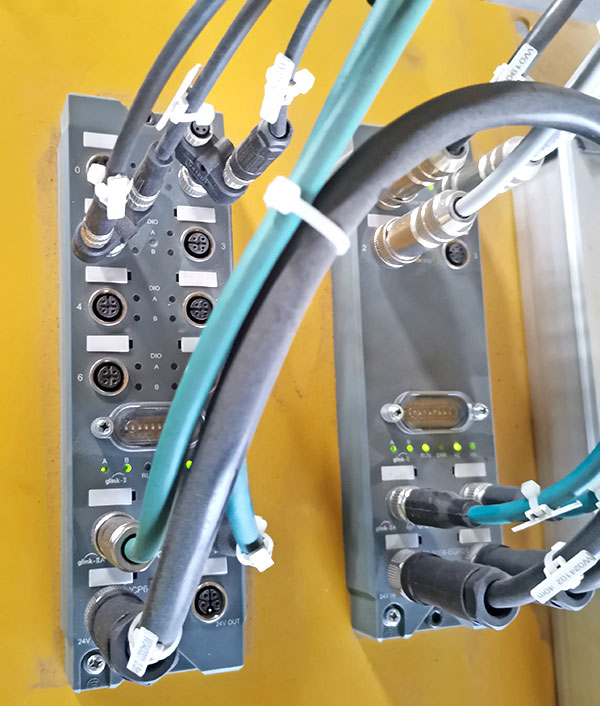

Excellent bottom communication technology with independent technology Gigabit Ethernet industrial bus technology Glink-II can achieve the data exchange rate reaching the millisecond level. The efficiency of the whole line is higher than that of the traditional control method (Siemens 100M bus) due to the fast data exchange speed, and its safety and reliability are also improved.

The optical fiber connection technology is adopted as the bus technology, featuring satisfactory compatibility and connectivity. Be compatible with CAN, PROFI-BUS, and HART bus technologies.

Gigabit network, as the main form of future industrial communication, is an excellent technology for building industrial interconnection.

To cope with all kinds of harsh environments.

High-strength aluminum alloy die-casting shell

High safety regulations

IP67 encapsulation

The rack free system is configured with a die-cast aluminum alloy shell. And its RGBT power components are designed on the backplane of the aluminum base body with a heat sink to solve the problem of high power and heat dissipation. And a 4-level high-safety design is applied to the circuit board. Its system architecture is designed according to Huawei's design idea with the sealing level achieved IP67 (and the cabin is IP68 under the limitation of domestic waterproof joints). It can be used in harsh environments and in the open air.

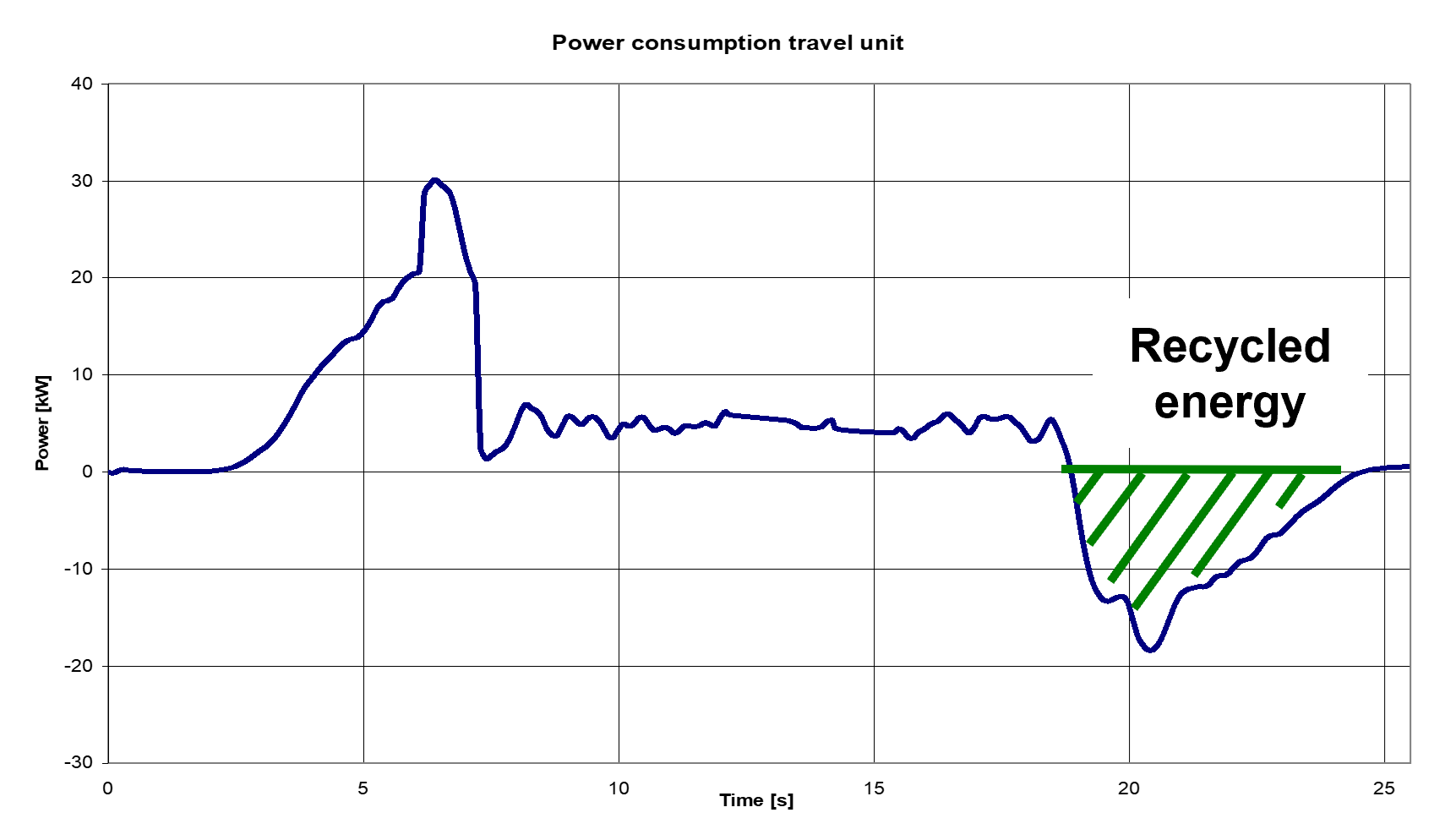

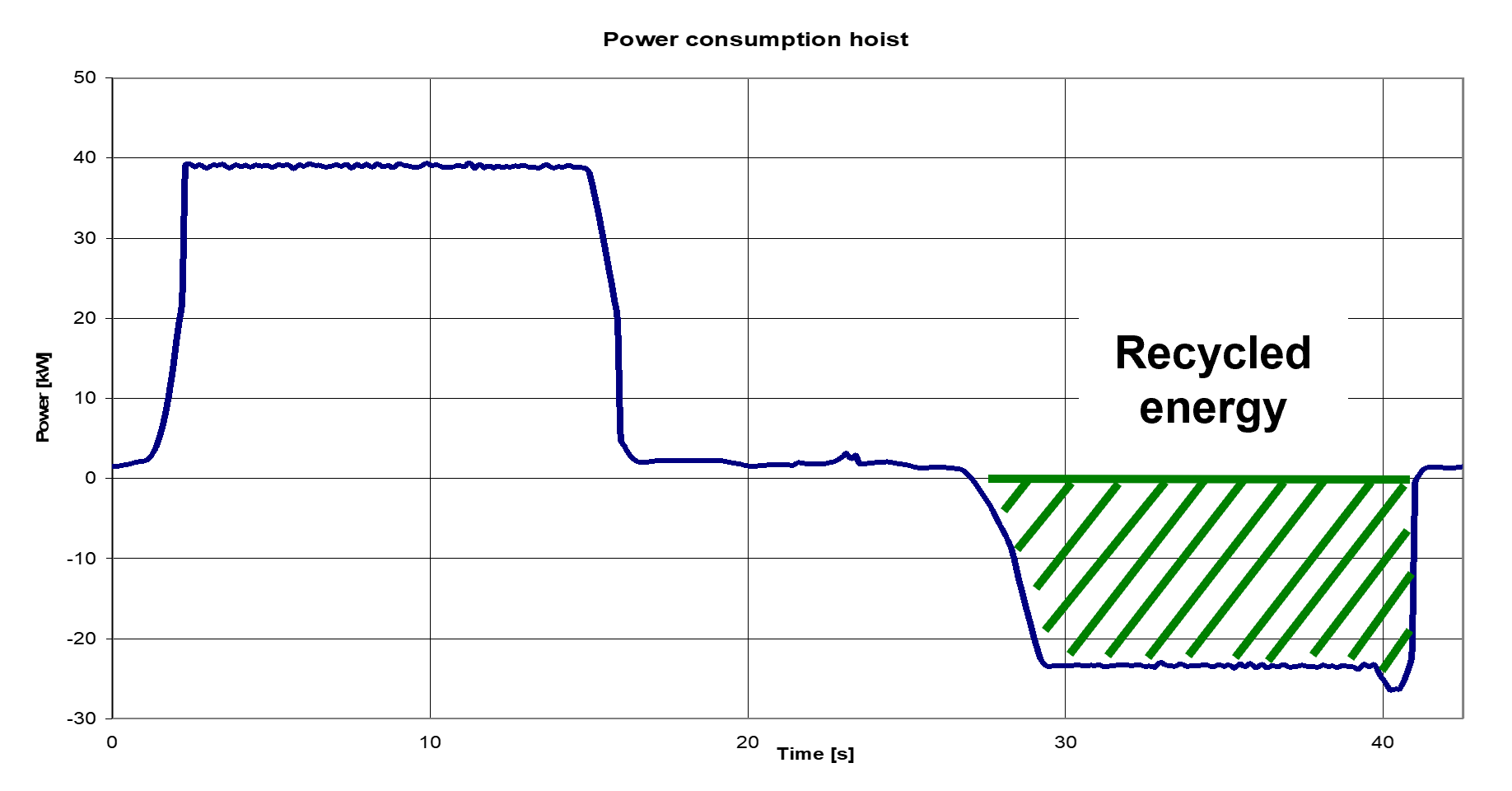

DC common bus power regeneration technology is leveraged in the rack free system.

Energy saving for more than 40%

-

X-axis/strong> regenerative power unit

X-axis/strong> regenerative power unit -

Z axis

Z axis

Distributed Remote I/O System

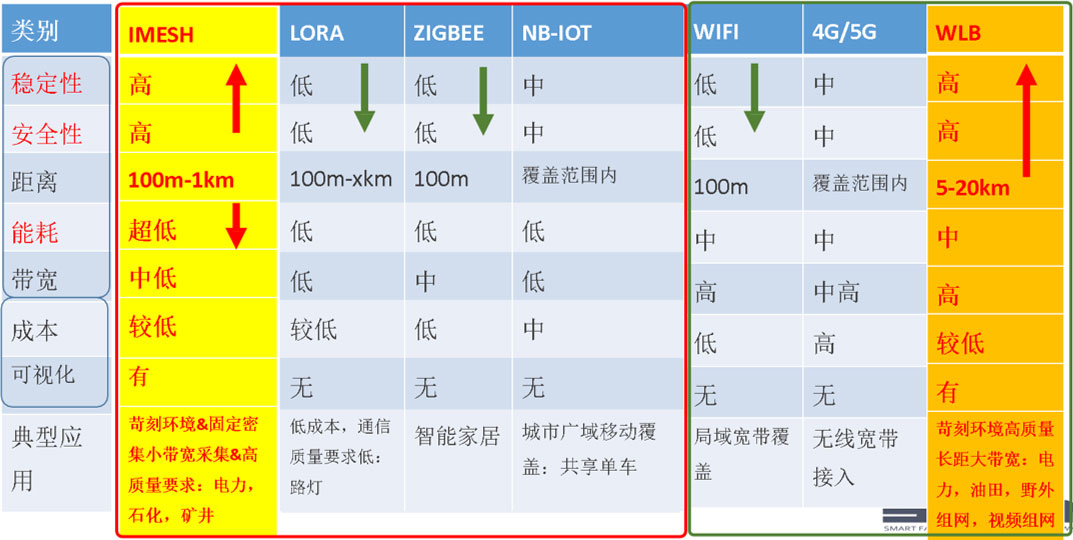

Factory's own wireless & communication network free of network outage The industrial Ad-Hoc network technology is adopted in the rack free system.

A "dummies" control system requiring no electrical engineer (No need for electrical drawing, wiring, installation, and commissioning)

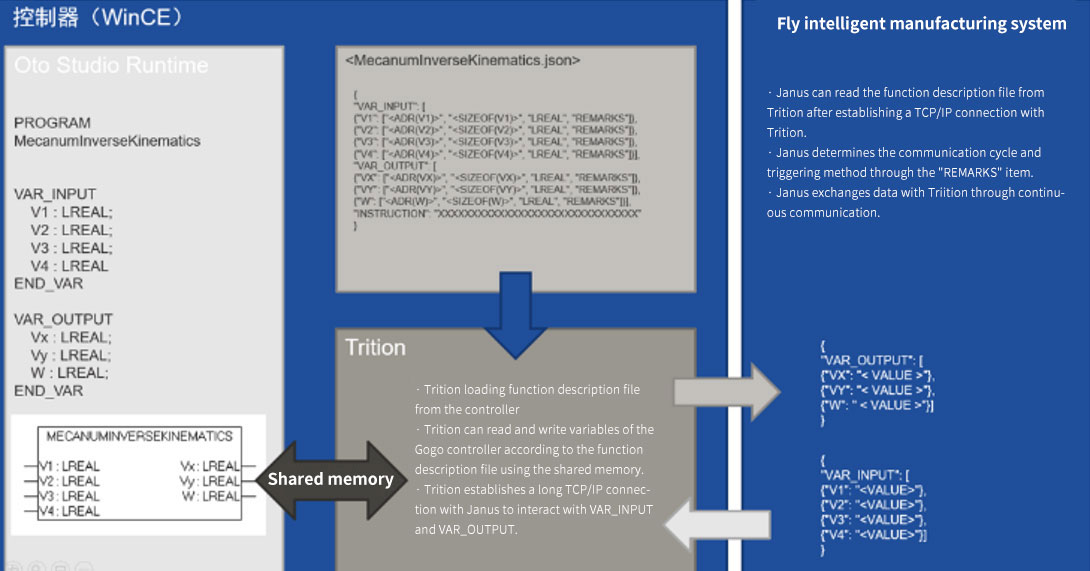

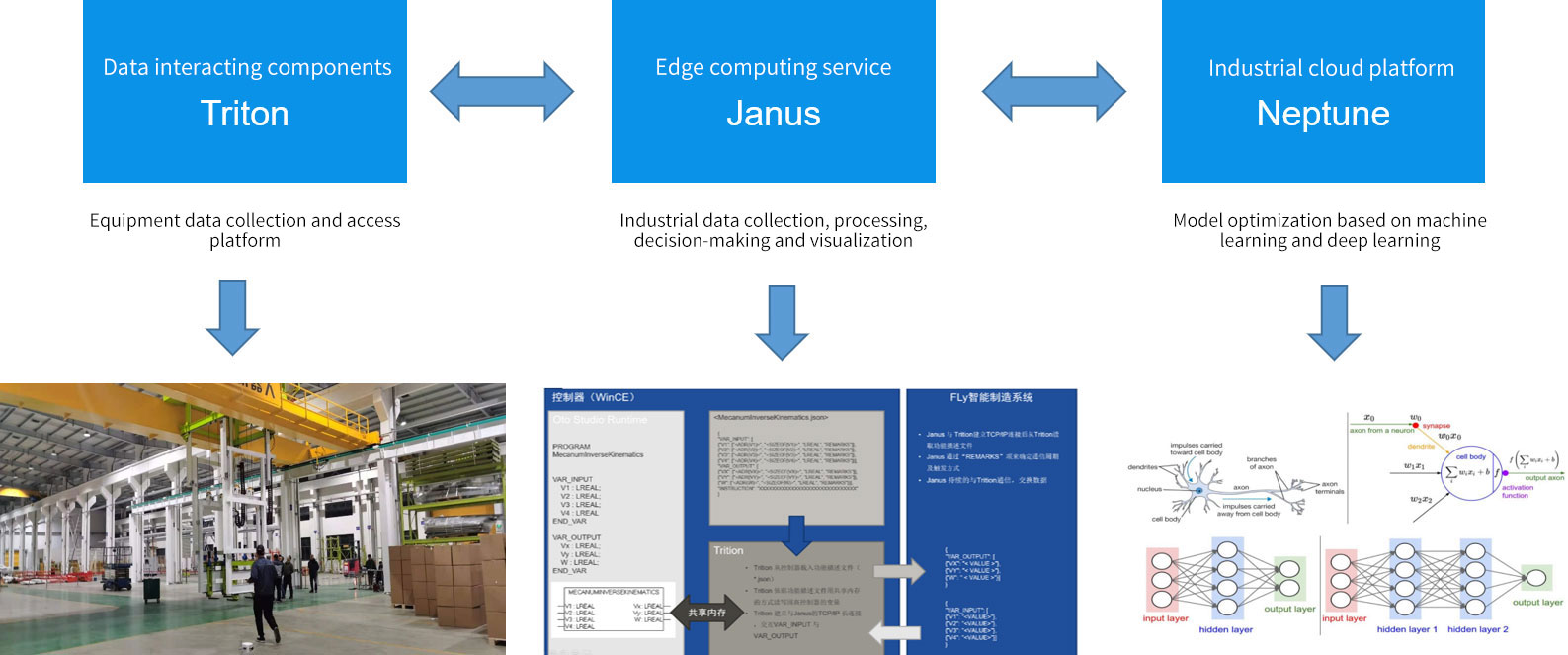

Low-code programming system: Database + process flow diagram for dynamic reorganization

-

Fly master control host T800

The arrival of the low-code era -

An operating system requiring no code programming

Development of intelligent management software system based on deep learning

Front-end operating system interface of the rack free control system

SU30 system connection

R& D Course

Rack Free Control System Application Cases

-

![A Certain Company's Intelligent Cutting Line Intelligent Driving Project]() A Certain Company's Intelligent Cutting Line Intelligent Driving Project

A Certain Company's Intelligent Cutting Line Intelligent Driving Project -

![The Application Of A Containerless System For A 460-Meter Long Welding Wire Reel Empty Reel Transportation Line In A Certain Company]() The Application Of A Containerless System For A 460-Meter Long Welding Wire Reel Empty Reel Transportation Line In A Certain Company

The Application Of A Containerless System For A 460-Meter Long Welding Wire Reel Empty Reel Transportation Line In A Certain Company -

![A Certain Power Company (Cable Protection Pipe Warehouse)]() A Certain Power Company (Cable Protection Pipe Warehouse)

A Certain Power Company (Cable Protection Pipe Warehouse) -

![Power Industry- State Grid (Cable Protection Pipe Warehouse)]() Power Industry- State Grid (Cable Protection Pipe Warehouse)

Power Industry- State Grid (Cable Protection Pipe Warehouse) -

![A Sorting Line For Finished Products Of A Certain Company's I-Shaped Wheels]() A Sorting Line For Finished Products Of A Certain Company's I-Shaped Wheels

A Sorting Line For Finished Products Of A Certain Company's I-Shaped Wheels