The Application Of A Containerless System For A 460-Meter Long Welding Wire Reel Empty Reel Transportation Line In A Certain Company

Mass of heavy-duty I-shaped wheels are circulated in the welding wire production process. With the stacking and packaging of various finished welding wire reels, the production workshop has high equipment density with a total length of 460 meters and more than 160 wire drawing machines. Traditionally, general-purpose handling equipment cannot be travelled for a super long distance. Multiple units can only be arranged in a segmented manner. Basically, one unit must be arranged within a range of 50 meters, with at least 9 units required. For the truss robot with the rack free system, the control system is set on the truss robot body with a wireless connection. Not limited by travel, the number of robots can be set as per the beat. Only 4 robots were arranged in this project to meet the beat. And there is another advantage. Other robots can replace the failed truss robot equipment to complete the sorting work without affecting production. In this way, the failure has no impact on the production and the production line.

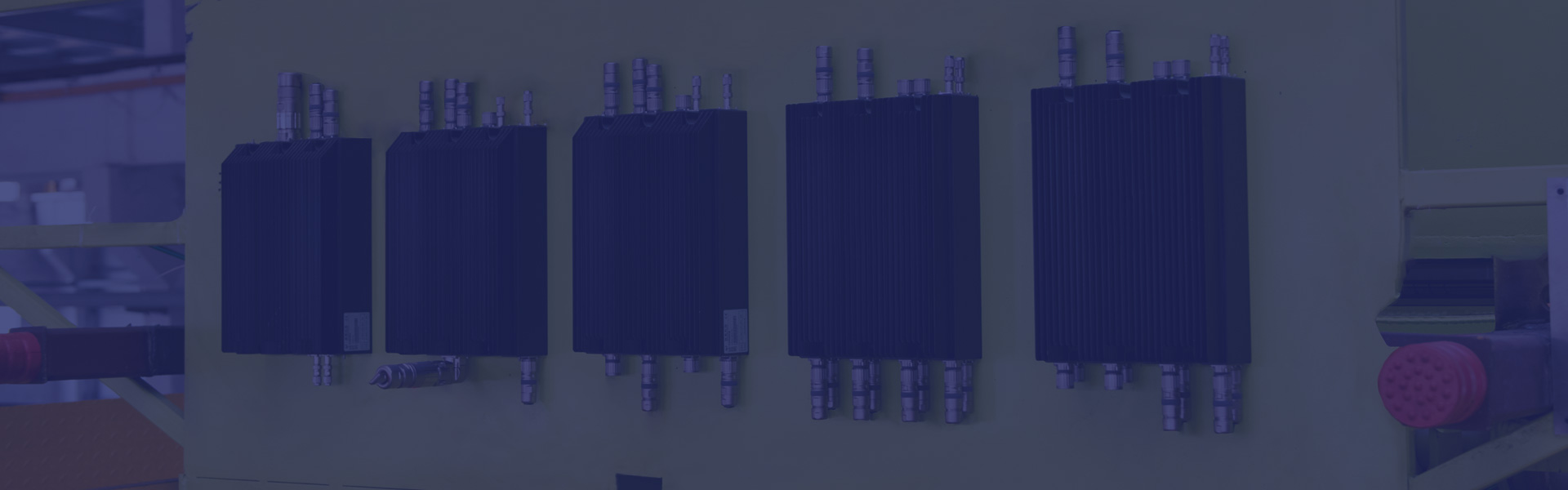

The rack free control system is adopted, which is composed of 1 rectifier module, 1 control module, and 1 one-to-four driver. There is neither a control cabinet nor wiring construction.